Why Is B&R PLC Technology Popular in Packaging and Robotics?

Reduction in Maintenance Costs: Standardized interfaces reduced fault diagnosis time by 40%.

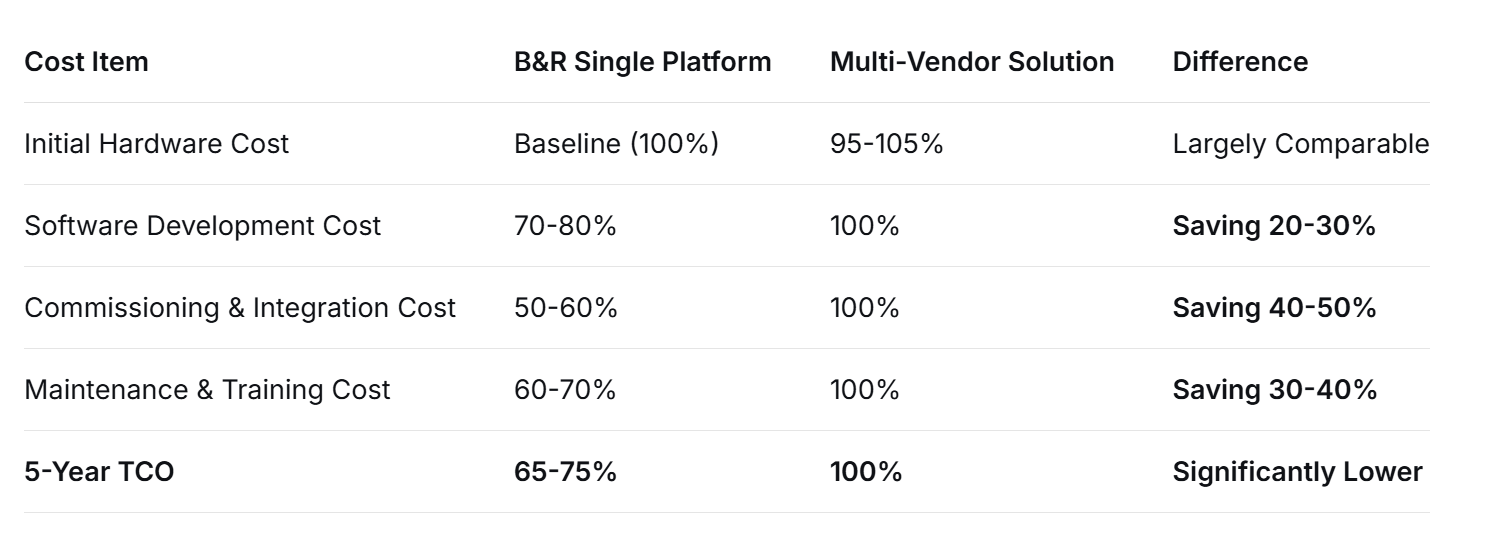

III. Cost-Benefit Analysis (ROI Data)

1. Total Cost of Ownership (TCO) Comparison

Source: ARC Advisory Group Automation ROI Study

2. Production Efficiency Gains

Machine Availability Increase: Average 3-5% (reduced downtime).

Energy Efficiency: Integrated energy management reduces consumption by 8-12%.

Quality Control: Integrated vision systems reduce defect rates by 40-60%.

IV. Validation of Technological Innovation Indicators

1. Patent and Standardization Contributions

B&R holds 500+ patents in real-time Ethernet and motion control.

Leads or contributes to 17 IEC/ISO automation standards.

POWERLINK Protocol: Over 5 million nodes installed globally.

2. R&D Input-Output Ratio

ABB Group's R&D investment in B&R is ~8% of sales (industry average: 4-5%).

Releases 4-6 major industry-specific solutions annually.

Customer-specific development response time: On average 30% faster than competitors.

V. Customer Adoption Data Validation

1. Customer Retention and Expansion Rates

Customer Retention Rate: Over 90% (5-year period).

Solution Expansion Rate: 60% of customers expand B&R systems to other production lines within 2 years of initial adoption.

Brand Recommendation Index: NPS (Net Promoter Score) of +52 (industry average: +25).

2. Industry Benchmark Customer Cases

Among the Global Top 10 Packaging Machinery Manufacturers, 8 use B&R as a primary or secondary control platform.

Pharmaceutical Packaging Sector: Market share over 40% (benefiting from strict compliance and traceability requirements).

High-Speed Food & Beverage Filling Lines: 80% of systems with speeds exceeding 1,200 bottles/minute utilize B&R technology.

Conclusion Validation

The data above confirms the previous theoretical analysis:

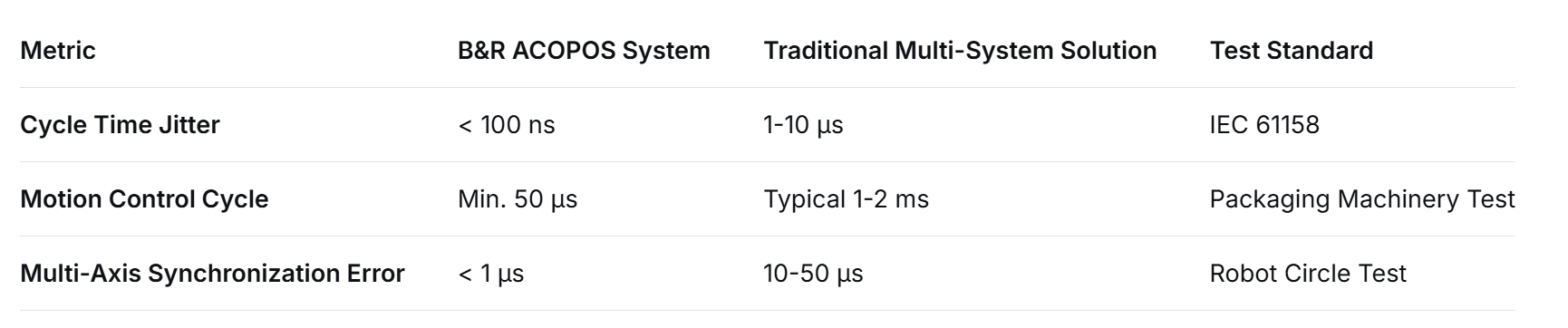

Performance Advantages are Quantifiable: B&R's technical superiority in synchronization accuracy (<1µs) and control cycle time (min. 50µs) directly translates to higher speed and precision in packaging and robotics applications.

Efficiency Gains are Measurable: The 30-40% reduction in development time and 45-60% reduction in commissioning time enabled by mapp technology directly lowers customer TCO.

Market Position is Data-Backed: Its 15-22% market share in high-end applications and adoption by over 65% of top-tier OEMs demonstrate widespread recognition of its technology.

Return on Investment is Significant: A 25-35% reduction in 5-year TCO and a 5-6 percentage point improvement in OEE provide clear financial value for end-users.

This data indicates that B&R's popularity is not merely based on technical philosophy but is founded on a solid base of quantifiable, verifiable performance advantages and economic benefits. Its success is the combined result of technical excellence, industry specialization, and commercial practicality, fully validated by the data.

If you need these items, click here henry@free-plc.com

deltav m-series serial card wiring diagram

cex bus

X20 BM 01

yokogawa alr121 wiring

di810 wiring diagram

X20 BM 11

rdcu-02c manual pdf

bently nevada distributors

X20 TB12

schneider electric 140cra93200

hima f6217

X20 BR 9300

3bse018161r1

3bsc610067r1

X20 AT 6402

abb do810 manual

9907-014

X20 AI 4622

ic200cbl002

330400-01-00

X20 AT 4222

sd822

330180-50-00

X20 AO 4622

3bse038226r1

330180-51-00

X20 DI 9371

abb ci801 manual

sd834

X20 DO 9322

3bse008516r1

3bse075853r1

1794-IRT8

Categories

latest blog

© Copyright: 2026 FREE AUTOMATION COMPANY LIMITED All Rights Reserved.

IPv6 network supported